Swathing vs. Direct Combining for Canola Harvest

Good agronomic practices play a crucial role in achieving optimal canola yields, but the importance of proper harvest management cannot be overstated. As we enter the harvesting season, farmers in Western Canada are confronted with a crucial question: should they adhere to the conventional practice of swathing or embrace the contemporary technique of direct combining (also referred to as straight cutting) for their canola harvest?

This decision holds the key to unlocking the full potential of their efforts throughout the year.

As the Canola Council of Canada’s Canola Encyclopedia explains, “Both swathing and direct combining (or straight cutting) are effective ways to manage canola harvest. Each method has its own advantages and disadvantages. Some farms will use both methods to manage efficiencies and time at harvest.”

In this blog, we’ll further explore the advantages and disadvantages of each method, providing insights to help farmers make an informed choice that aligns with their goals and aspirations.

Swathing: Traditional Wisdom Meets Modern Efficiency

Swathing, a time-honored method in canola farming, involves cutting the crop and laying it in windrows to dry before harvest. One of the most significant advantages of swathing is the potential for an earlier harvest. This can be especially crucial in regions with shorter growing seasons such as in Western Canada or for farmers looking to grow fall seed crops. By initiating the drying process before harvest, swathing can lead to a more uniform seed maturity, providing a higher-quality end product.

Moreover, swathing offers the benefit of greater flexibility and reduced pressure on timing. Unlike other crops, canola retains its quality in the swath better, which means the grower has a more forgiving window for starting harvest. This flexibility can be a lifesaver when unexpected weather events loom on the horizon.

Swathing also aids in biomass dry-down. The crop experiences a more uniform dry down, leading to reduced shatter losses during harvest. Additionally, this method contributes to better weed seed dry-down and decreased high-moisture dockage in the grain sample. This is important, as proper storage conditions and grain quality are pivotal factors in the post-harvest phase.

Direct Combining: Efficiency and Yield Enhancement

Direct combining, on the other hand, has gained popularity in recent years due to the method’s efficiency and potential to increase yields. This process eliminates the need for swathing by directly harvesting the standing crop. One of the most significant advantages of direct combining is reduced labor and equipment requirements, which can be a game-changer, especially for farms with limited manpower or looking to streamline their operations.

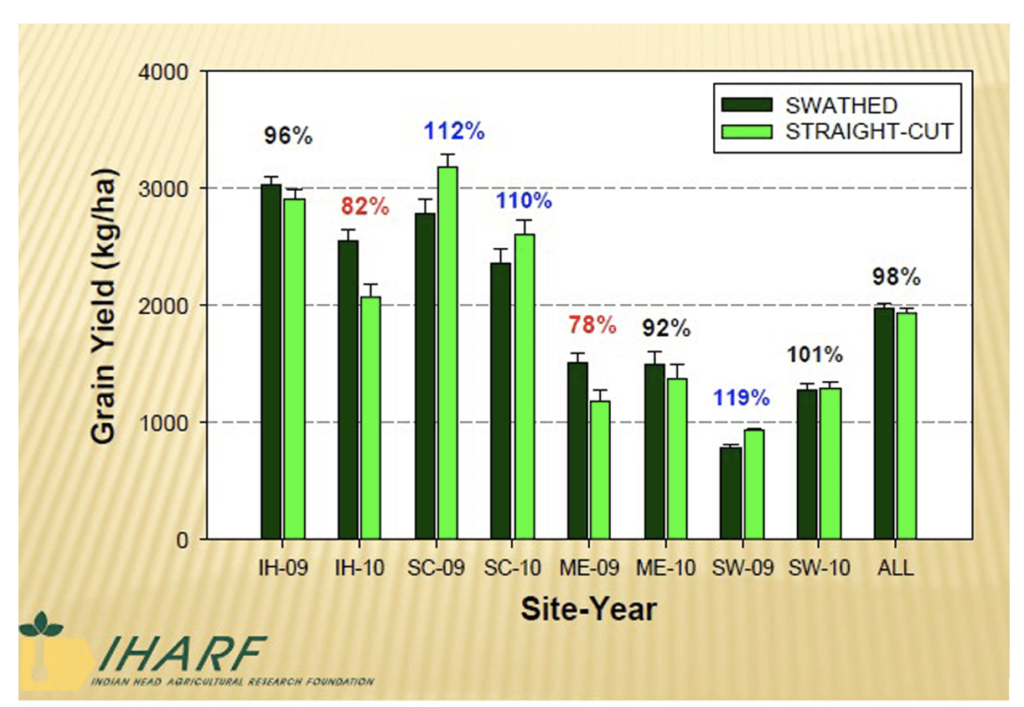

Additionally, the flexibility offered by direct combining is a major draw. Farmers can choose the direction and area of the field to be harvested, adapting to the unique layout of their land. This method also contributes to increased seed size and yield. By avoiding the drying period of swathing, canola retains more of its natural oils, potentially leading to higher yields and better financial returns.

Furthermore, direct combining can result in logistical efficiencies. Without the need for swathing and the subsequent waiting period for drying, the total harvest process can be accelerated, reducing the overall time needed to complete the harvest. This is particularly important for farms with large acres or those operating under tight schedules.

The Decision: Factors to Consider

In the end, it is important to remember that both methods offer distinct advantages that cater to different operational needs. Swathing provides a more measured approach, offering flexibility in timing and the potential for higher seed quality. Direct combining, on the other hand, emphasizes efficiency, reduced labor, and potentially higher yields.

Ultimately, the choice between swathing and direct combining boils down to the specific conditions and goals of your farm. When making this decision, consider factors such as your region’s climate, the length of your growing season, available labor and equipment, and your post-harvest storage capabilities.

Your choice should align with your overarching objectives.

But remember, it is crucial to thoroughly evaluate each canola field before the seed color change (SCC) reaches 60%. This will help you determine whether swathing or direct combining is the better option. This early evaluation ensures timely swathing if direct combining isn’t suitable for a particular field. When it comes to direct combining canola, the choice to use a desiccant or pre-harvest aid is at your discretion.

Read more about Canola Harvest Management here

Agracity’s MicroPhos Canola

Agracity’s MicroPhos Canola is a breakthrough in canola cultivation, designed to empower your crops with the nutrients they need for robust growth and exceptional yields.

Power Phos is a coating which surrounds the granule and acts as a “shield” to the negatively charge soil conditions. The Power Phos shield attracts and binds the ions that tie up Phosphorus making it more available to your crop.