How Can You Improve Your Herbicide Performance This Year?

2024-11-25

With herbicides being a significant part of your crop input costs every year, it makes sense to think about how to get the best performance out of your herbicide purchase, instead of spending more on the latest, more expensive herbicides that may not actually perform much better. Below are some tips that can help you improve the performance of the herbicides that you use this year.

Get your crop off to a competitive start.

A strong, healthy and thick crop stand can compete more effectively with weeds to help keep crops cleaner throughout the growing season, the cultural practices listed below can help get your crop off to the best start.

- Fertility program: Start every year with a good fertility program. You spent a lot of money on fertilizer every year, make sure that your crop gets what it needs. Start with a soil test. Fertilizer is one of the biggest expenditures on your farm, so soil testing makes a lot of sense. Following updated soil test recommendations can help pinpoint precisely what each field and crop needs and will consider any carryover from last year or any severe deficiencies that could hinder crop growth.

- Fertilizer placement: Placement of fertilizer to encourage crop growth and competitiveness is another cultural weed management tool. Several studies in Saskatchewan and Alberta have found that, generally, banding nitrogen (N) fertilizer below the soil surface helps crop seedlings get to the nutrients more quickly, increasing crop competitiveness. Additionally, banding N close to the time of seeding also favors crop competitiveness compared to fall banding.

- Pre-seed burnoff: Use a pre-seed burnoff to help your crop get off to a clean start. This is especially important if you have overwintered weeds such as stinkweed, dandelion, narrow-leaved hawk’s-beard or other tough to kill winter annuals or perennials, as these are much harder to kill in crop, and waiting until fall can cost you in yield, dockage, or harvest issues. Consider adding a tank mix product with a different mode of action with your glyphosate to help reduce the risk of herbicide resistant weeds, especially if you are in an area with group 2 and 9 resistant kochia.

- Seed quality: Studies over the years have consistently shown that high quality seed can result in stronger crop emergence and more vigorous seedlings. Make sure that you start with high quality seed, whether purchased or bin run. Your seed supplier can provide you with quality information when you purchase; if you are using home grown seed make sure to get a quality analysis done prior to seeding.

- Seeding rate: Consider increasing your seeding rates and use narrow row spacings on your seeding equipment. Multiple studies have found that a higher seeding rate at narrower row spacing improves crop competitiveness and herbicide performance. spacing has also been proven to help the crop compete with weeds. In cereals, very narrow row spacing was found to reduce overall weed competitiveness. Row spacing of 9 to 12 inches is generally used by most farmers. As a result, seeding rate may be more important than row spacing. An additional benefit of a higher seeding rate is more even emergence of tillers in cereals which can help improve disease control.

- Seeding date: Generally, earlier seeding allows the crop to get established and better compete with weeds. But delayed seeding can allow for management of a greater number of emerged weeds prior to planting, sometimes resulting in lower weed emergence after the crop is planted or allowing mechanical control such as tillage to help control weeds.

Scout your fields before deciding on application.

(information from the Saskatchewan Crop Protection Guide published by the Saskatchewan Ministry of Agriculture)

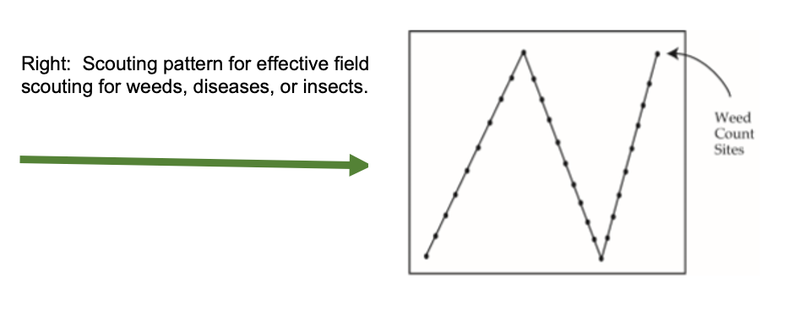

Accurately assessing the type and number of weeds in the field will help you determine if a spray operation is necessary. The entire field should be walked to get a feel for the distribution and species of the weeds present. A minimum of 20 weed counts should be taken across the field. A smaller number may be used but be aware that accuracy decreases as the number of counts gets smaller. Count the number of weeds in a 1 m2 and divide the total number of weeds by the number of counts taken to obtain an average for the field. Some weeds are not distributed uniformly and may be found in patches (for example, Canada thistle) or in low spots. As well, the type and number of weeds found along the field edges may be very different from those found inside the field. These areas should be considered separate from the rest of the field. If possible, patches, low spots, and field borders should be treated separately, as field-wide spraying may not be required. Look out for new invading weeds and patches of herbicide-resistant weeds. Herbicide-resistant weeds and new invaders should be removed (manually if necessary), regardless of their number, to prevent them from spreading and becoming a serious control problem. Mapping your field’s weed problems will allow you to monitor the spread of weed patches over time and help you assess the effectiveness of your control program.

Know your herbicide mode of action and best time of day to apply.

Consider the type of herbicides you are applying this year. Is it a contact herbicide, such as a group 5,6,7, 10, 14,15, 22, or 27? These are all contact-type herbicides and need warm, moist, sunny conditions with active plant growth for optimum control. These types of herbicides will work best in the middle of the day when photosynthesis is at its highest and when plants are best able to absorb herbicides. Are you using group 1, 2, 3, 4, 9 or other systemic herbicides? Systemic herbicides need good plant growth and good growing conditions, such as warm temperatures and good moisture and active plant growth for best performance. Ideal conditions for these types of herbicides will be the earlier part of the day when plants are most actively growing vs. evening when plant growth is slowing down. If you are not sure of the herbicide group you are using, the AgraCity product guide and website contain herbicide group information for each AgraCity product.

Understand the effect of growing conditions on herbicide performance.

Plants are systems of complex biological processes and changes in these biological processes due to growing conditions can impact how herbicides will perform and interact with both the crop and the weed. These biological processes in the crop normally allow the herbicide to be degraded quickly. If these same biological processes are not functioning normally the weed may be able to detoxify the pesticide before dying and recover from the application. In most cases both crop and weed must be growing or functioning normally for pesticides to provide expected performance and/or crop tolerance. Generally speaking, most herbicides work best in warm moist conditions with temperatures between 12 and 24 °C. Application during adverse weather conditions such as extreme heat, cold, frost, drought, dusty conditions or flooding either at the time of application or shortly before or application can slow or stop the biological processes in the crop and the weed, which can result in reduced herbicide performance and or crop injury as the crop may not be able to either absorb or detoxify the herbicide properly or weed control will be reduced.

Know your weed and crop staging.

Different herbicides have different crop and weed stage requirements.

Crop stage: Herbicide application if the crop is either too small or too big can impact crop tolerance as well as increase the risk of yield loss as the crop has to detoxify the herbicide and early or late applications make it harder for the plant to do this. Provincial crop protection guides are a good source of information to understand crop staging for different crops.

Weed stage: If weeds are either too small or too big performance can be reduced, or the weed may not die at all because weeds will not effectively absorb the herbicide if it is out of the staging window. Always check the product label to understand the staging for both the crop and the weeds, and if you are not sure, check the AgraCity product guide, website, or call your AgraCity business representative.

Follow recommended application rates and water volumes.

Herbicide application rate: While it can be tempting to reduce application rates to save money, following the correct application rate is critical to product performance; if the rate is too low, performance may be reduced, and if the rate is too high, the risk of crop injury rises.

Always follow the application rate outlined on the product packaging, product guide, or the label. If you are not sure, you can always check the AgraCity product guide, website or your AgraCity business representative.

Water volume: The time and effort it takes to haul water can be frustrating. However, using less than the recommended water volume can negatively impact product performance due to loss of coverage, especially with application during stress conditions such as drought. Less than recommended water volumes can also increase the risk of crop injury, particularly with contact herbicides and if you are using low drift nozzles. Stick to recommended water volumes during application to avoid the risk of non-performance or crop injury, and check with your spray nozzle supplier for recommendations on nozzles. The website www.Sprayers101.com is also a good source of information on water volumes and application in general.

Don’t forget about surfactants.

Many products will require you to add surfactant to ensure optimum performance, failure to do so could result in lower than expected weed control. Make sure to check the product label, the AgraCity product guide or website or contact your AgraCity representative if you are not sure whether you need to add surfactant or not, and if so, which surfactant is recommended to go with the product in question. Not all surfactants are the same; always check to make sure you are using the right one, there are a few different surfactants on the market, not all of them are the right fit.

The final step: mixing and application.

Pay attention to what is happening during mixing and application. Improper mixing can result in poor results or crop damage. Before you add any product make sure the sprayer is filled to ½ full and start gentle agitation before adding any products. Granular or soluble powder products may take extra time to dissolve, so make sure to allow extra time, and check to ensure they are fully dissolved before adding additional products. If you are using flowable liquids (OC or SC products) add those next. Emulsifiables (esters) can then be added, followed by surfactants. Do one final check before application to make sure all products are suspension and that you have added the required amount of water. If for some reason application is stopped before the tank mix empty, re-agitate thoroughly before resuming application, and remember that some products must be used within 24 hours.

Finally, don’t forget to do a thorough tank cleanout after application is complete, especially if you are changing crops next time around. Herbicide residue in spray tanks, especially concentrated herbicides in the group 2 mode of action family, can easily get trapped in screens, booms and nozzles. Take the extra few minutes to conduct a thorough cleanout by doing 3 rinses. The first rinse should be with water, the second rinse by using a high-quality tank cleaner like All-Clear® or Finish®, and a final rinse with water. Don’t forget to check your end caps and nozzles before you finish up and move to a different crop.

AgraCity has fungicide options for every acre on your farm this year. AgraCity has the best prices on a complete line of pulse products, including fungicides, herbicides, inoculants, micronutrients, foliars and desiccants. Talk to your local AgraCity business representative, go to www.AgraCity.com/ or call 1-844-269-3276 to discuss how AgraCity can help manage your pulse crop input costs.